Sandao SD-704 Specialized adhesive for electronic components 45G

Product Summary:

Mishima SD-704 silicone sealant is a single component room temperature curing silicone sealant. When exposed to air, it reacts with trace moisture in the air to form a flexible silicone rubber elastomer after curing. After curing, it has excellent high and low temperature resistance, the working temperature is -50℃ ~ 200℃, and the peak temperature resistance can reach 250℃. Stable performance, good electrical insulation, aging resistance, moisture resistance, good bonding performance. It is suitable for bonding and sealing between various metals, metal and non-metal materials.

Product features:

Mishima SD-704 silicone sealant is a single component room temperature curing silicone sealant. When exposed to air, it reacts with trace moisture in the air to form a flexible silicone rubber elastomer after curing. After curing, it has excellent high and low temperature resistance, the working temperature is -50℃ ~ 200℃, and the peak temperature resistance can reach 250℃. Stable performance, good electrical insulation, aging resistance, moisture resistance, good bonding performance. It is suitable for bonding and sealing between various metals, metal and non-metal materials.

Product use:

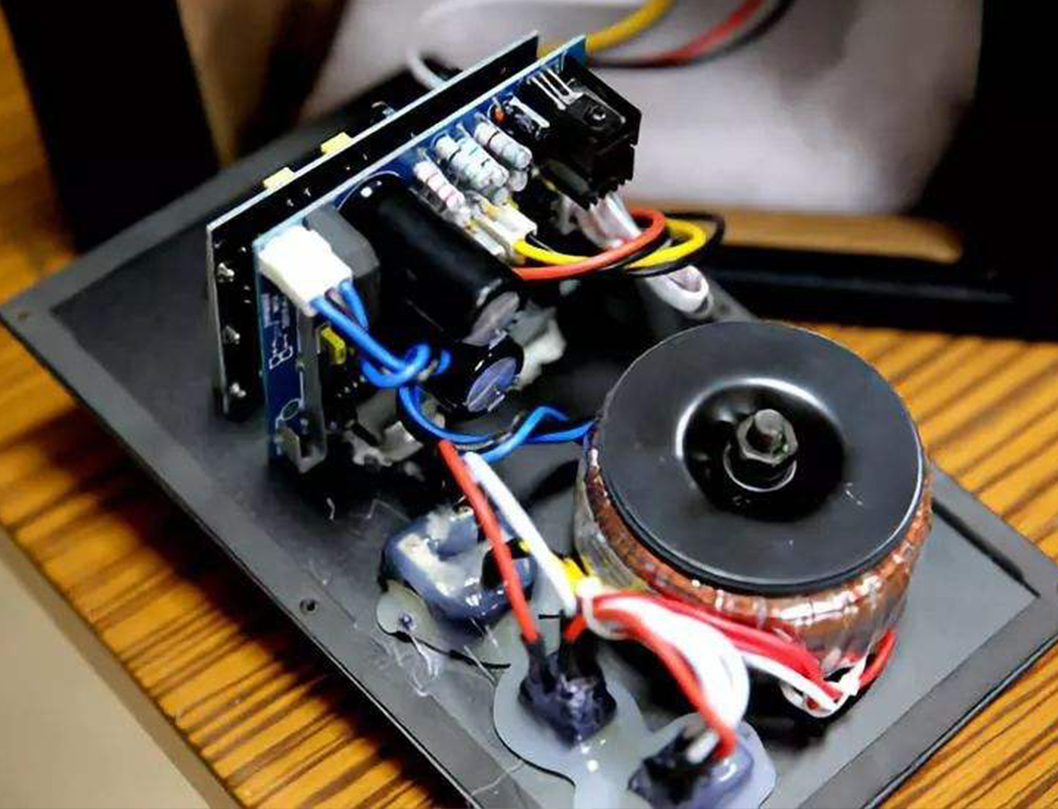

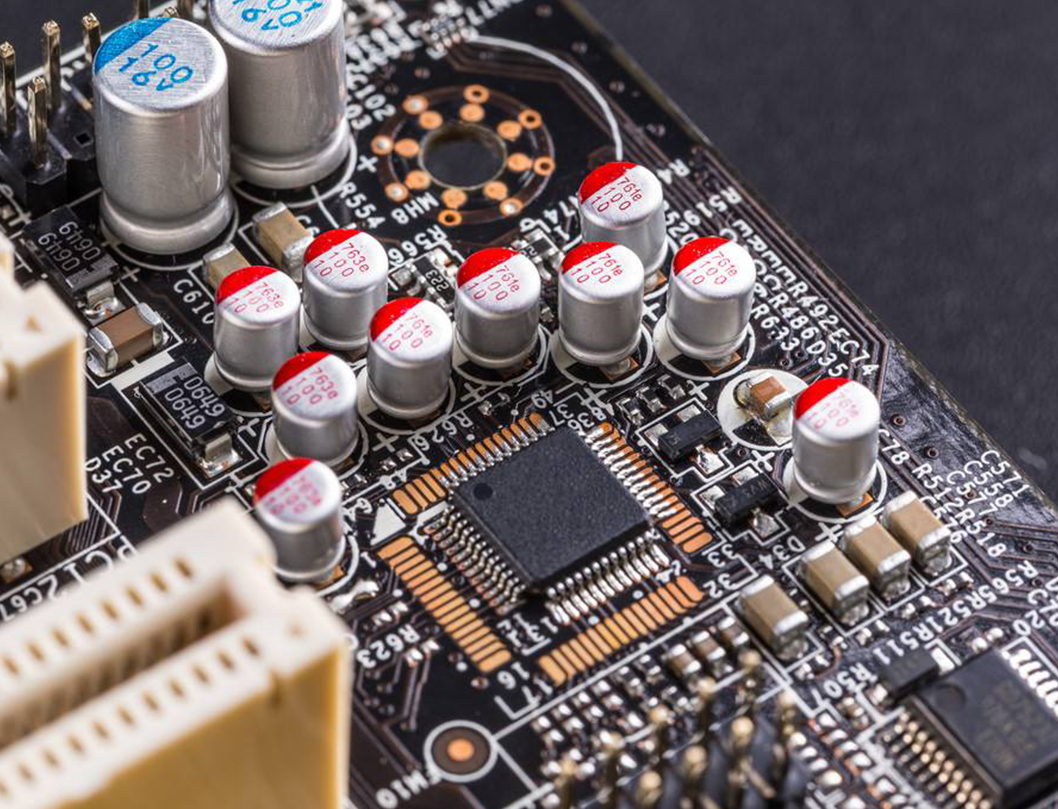

Mishima SD-704 silicone sealant as bonding, sealing, insulation, moisture-proof materials, widely used in electronic components, semiconductor materials, electronic appliances and other equipment bonding, sealing, electric heaters, electronic instruments waterproof, sealing and electronic components, etc. Specifically, such as the sealing of the electric heating end, the bonding of the small motor tile and the metal shell, the bonding sealing of the automobile lamp, the optical instrument and the lens, the bonding of the electronic instrument shell, the insulation protection of the motor, the bonding sealing of the electronic components, etc.

Technical performance:

Precure property

Name: SD-704

Appearance: White viscous liquid

Surface drying time (25℃,min) : ≤10

Mechanical properties after curing

Tensile strength (MPa) : ≥1.0

Elongation at break (%): ≥150

Shear strength(MPa)AL/AL: ≥0.8

hardness(shore A): 30~40

Electrical properties dielectric constant(100KHz) :≤3.0

Dielectric strength(KV/mm): ≥15

Volume resistivity(ΩNaN): ≥1.0×1014

How to use:

1. After the general cleaning and drying of the components, the product is extruded from the metal hose for sizing, and the rubber material contacts the water in the air, that is, from the surface to the inside curing

2, the coated parts are placed in the air, and can be put into use after 24 hours of room temperature curing.

Note:

1, curing requires humid air, in the case of large bonding area may take a long time.

2, after the operation is completed, the unused glue should be tightened immediately, sealed and stored. When used again, if there is a little crust on the seal, it can be removed without affecting normal use.

3. Avoid contact with eyes, skin and clothing. Rinse with soapy water immediately after skin contact. If it spills into your eyes, rinse immediately with plenty of water. If you still feel unwell, go to the hospital for examination.

4. If the dispenser is used for sizing, it is recommended to soak the dispenser needle in a container containing silicone oil when the operation is over or interrupted to prevent curing and clog the needle, and remove a small amount of glue in the needle when working again.

5. Storage: Stored in a cool and dry place below 30℃, 45g/ branch storage period is 12 months.

Inquiry

Previous: No More

Next: S-3911Single component LED light no fog no white waterproof adhesive