SD913W 100gram Tube White Silicone Glue For PC CPU Coolers GPU LED Thermal Conductive Glue

■Description

◆ Product Model: SD913 single component room temperature curing thermal silicone rubber

◆ Characteristics: This product is a single component silicone compound, white paste. Solvent-free, corrosion-free acid and alkali resistance, aging resistance, corrosion resistance, radiation resistance and good weather resistance, can be used at -60 ~ 260℃. The product has good electrical insulation performance, moisture-proof and shock-proof function, heat dissipation performance and bonding performance, and can fully meet the bonding requirements of electronic components.

◆Environmental requirements: comply with RoHS directive and related environmental requirements

◆Citation standard :HG/T 3947-2007 single component RT-vulcanized silicone adhesive/sealant

■Apply

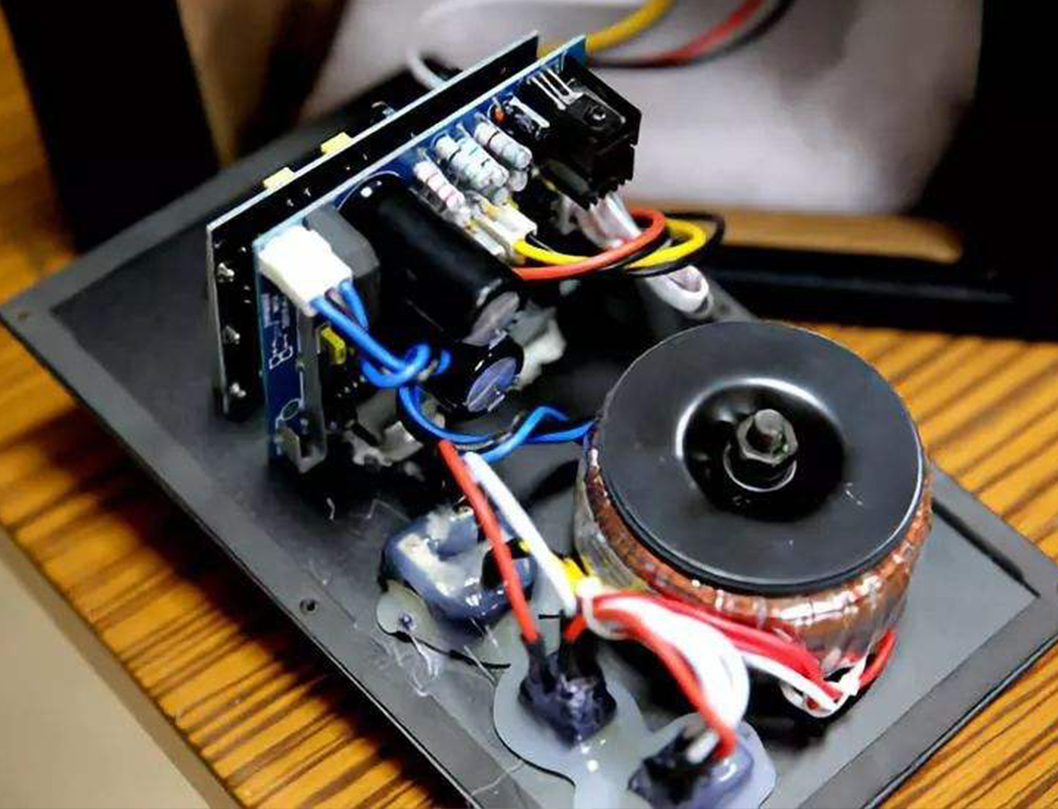

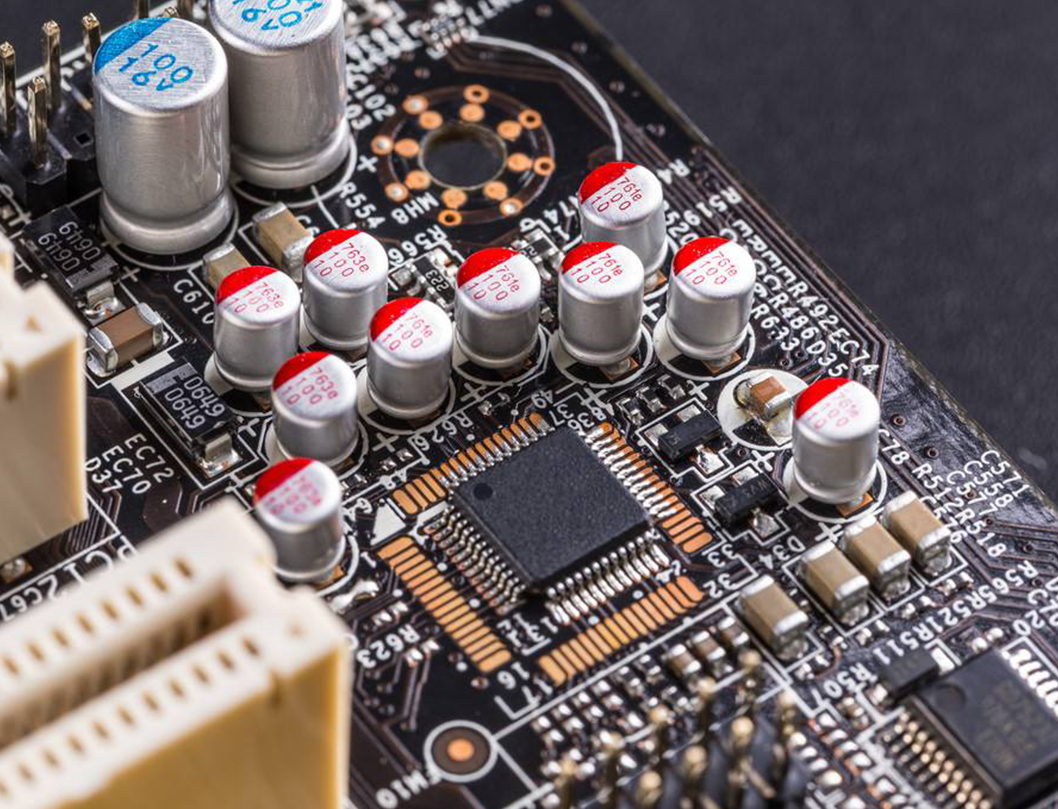

Thermal conductive silica gel can be widely coated in a variety of electronic products, electrical equipment in the heating body (power tube, thyristor, electric heating pile, etc.) and heat dissipation facilities (heat sink, heat strip, shell, etc.) between the contact surface, heat transfer media. Suitable for microwave communication, microwave transmission equipment, microwave special power supply, voltage regulation power supply and other microwave devices surface coating or integral pooping, such silicon materials for heat generation of electronic components, provide excellent thermal conductivity effect. Such as: transistors, CPU assembly, thermistors, temperature sensors, automotive electronic parts, automotive refrigerators, power modules, printers and so on.

■Electrical/mechanical properties (At TA=25℃)

|

argument |

symbol |

Test standard |

Performance index |

|

hardness shore A |

HA |

GB/T 531.1 |

50±5 |

|

elongation% |

δ |

GB/T 528 |

≥300 |

|

Tensile strengthMPa |

Rm |

GB/T 528 |

≥2.5 |

|

Shear strengthMPa |

σc |

GB/T 7124 |

≥2.0 |

|

Dielectric strengthkV/mm |

eo |

GB/T 1695 |

≥10 |

|

Dielectric constant1.0MHz |

ε |

GB/T 1693 |

2.5 |

|

Volume resistivity Ω·cm |

ρ |

GB/T 1692 |

≥1.0×1014 |

■Limiting parameter number (AtTA =25℃)

|

argument |

symbol |

Numerical value |

|

Surface drying timemin |

TFT |

1~5 |

|

Curing timeH |

TFT |

24 |

|

Thermal conductivityW/m·K |

λ |

1.0~1.5 |

|

Specific gravityg/cm³ |

s.g. |

1.7±0.1 |

|

Operating temperature |

TOPR |

-60°C To +260°C |

|

Storage temperature |

TSTG |

10°C To +25°C |

■Usage and precautions

※The adhesive sealing surface should be clean, the top of the nozzle should be cut off and sealed according to the dosage, put it on the packaging mouth, apply it to the construction surface (thickness should not exceed 6mm), and put it in the air. The surface of this product can lose its adhesive shape (surface dry) at room temperature for 3-10 minutes, and it will be completely cured after 24 hours. The heating of this product can not significantly change its curing speed.

※Unused adhesive material should be sealed and stored. When used again, if there is a little crust at the seal, it can be removed without affecting normal use. Glue in the storage process, the nozzle may also appear a small amount of curing phenomenon, can be removed after normal use, does not affect the performance of the product. The storage period is 6 months (25℃).

※This product is non-dangerous goods, but do not import and eye.

※This product cannot be mixed with other types of colloids!

■Packaging, storage and transportation requirements

※Transportation: Domestic (CN-GB), international (IMO, IATA, UN) no regulations. They are non-dangerous goods.

※Packaging: ① The packaging of the material has a certain protective effect and density on the material

The sealing function ensures that the material is not damaged during transportation.

② The product model, name, quantity and manufacture should be on the packing box

Manufacturer's trademark, production batch and other information.

③ The packing box should meet the requirements of moisture, shock, pressure and mildew.

※ Storage: Packaged products should be stored at ambient temperature below 26℃

Stored in a cool and dry environment, there should be no acidity, alkalinity or other in the surrounding air

He corrodes the gas, under the above conditions, from the date of production can be stored for six months, within which six months the material is still qualified.

※Packing specifications: 80G aluminum tube, 300mlPE tube, 2600mlPE tube